Equipment

TD 7500 CRP

Common Rail pump testing

Engine Power

15 Kw, controlled by the inverter

Testing of rail pressure sensor

Automatic cooling/heating system to control the test oil temperature

Lubricant oil tank of 8 liters

42L test oil tank

ITB.4R|X-A

Easily Accessible Filters & Waste Area

Ergonomic & easily

accessible illuminated working space. Fast mounting for all types of Injectors.

Quick access

to all inline filters for fast check-up and replacement located within your working area. A mess-free

compartment to work at, continuously draining to the waste tank.

BOSCH DCI 200

Time saving thanks to quick configuration and a 15-minute test time

Ergonomic design with sloping bottom

allows for a closer standing position and, therefore, greater working comfort on the test bench

Improved quality, reliability and transparency of Bosch injectors

thanks to fast and accurate testing, including IMA/NIMA coding

Always up to date thanks to regular online updates

Elimination of the use of additional accessories thanks to the automatic adjustment of the return counterpressure

BOSCH DCI 700

Ability to test Common Rail injectors with state-of-the-art VCC (Valve Closing Control) and NCC (Needle Closing Control) technologies for EURO 5 and EURO 6

High efficiency thanks to the patented swivel rail concept: no need for vulnerable high-pressure piping, reduced maintenance costs and easy configuration

Ergonomic design with sloping bottom, allowing for greater standing proximity and thus greater working comfort on the test stand

Elimination of the use of additional accessories due to automatic adjustment of the return backpressure

Always up to date thanks to regular online updates

Time savings due to quick setup and 15-minute test time

Increased quality, reliability and transparency of Bosch injectors through fast and accurate testing, including IMA/NIMA coding

Modular retrofit kits for commercial vehicles and off-highway common rail injectors - from Bosch and other manufacturers

Hartridge Toledo HEUI MASTER

Hydraulic Electronic Unit Injector Testing Made Easy

We have developed a platform which has

unparalleled benefits for the workshop

and covers most of the

HEUI injector parc.

Intuitive Touch Screen

Operated with magmah Touch software.

Splash Guarding

Each injector is secured into place to fully seal the nozzle for testing.

Unique Installation

Each injector is secured into place to fully seal the nozzle for testing, thanks to two quick clamping levering arms.

Test Plans

OE test plans with validated limits for all test conditions.

Application Kits

7 application kits are required to test the majority of HEUI injectors.

EPS 205 BOSCH

Universal clamp

Quick, no-fuss clamping of all injector types

Economical testing of common-rail diesel injectors and conventional nozzle- and-holder assemblies

Intuitive interface

Straightforward for technicians to learn and use with confidence

Built-in database

Integrate vehicle data and test values within efficient workflows

Automatic test bench

For CRI Piezo (Bosch, Denso, Siemens, Continental), Solenoid valve CRI (Bosch), Solenoid valve CRIN (Bosch), Solenoid valve CRI (third-party manufacturers), DHK/UI nozzles

Clear and accurate results

Demonstrate your expertise and service level to customers with a printed test report

Integrated suction device for minimal oil misting

Easy to keep the workshop environment clean and comfortable for technicians

200 V and 400 V options available

Choice that suits your workshop set-up

MAKTEST INJECTESTER UIP

Easy user interface with test plancreate and calibrate function

Adjustable cam stroke

Provides testing being as close to as standard working conditions of the injector.

UTS 1004 patented Cam Box allows to set the cam stroke without:

• draining oil

• removing cam

• adjusting timing

Easy user interface with test plan create and celibrate function

SRT Meansurement

UTS1004 is capable to measure the

Solenoid Response Time. SRT value

determines the condition of the solenoid,

assembly of the control valve with the

spring tension and valve stoke.

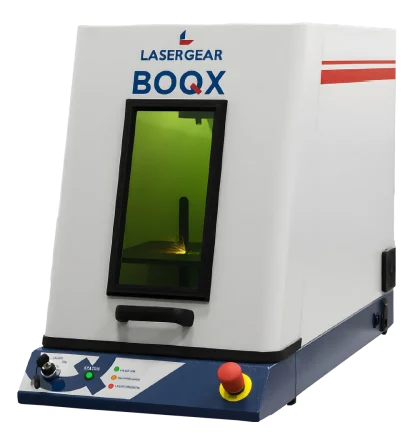

LASER GEAR BOQX

Compact Benchtop Enclosure

BOQX is a compact Class 1 laser enclosure, providing safe operator use without the need for protective eyewear.

Focus Finder Tool

Easily focus BOQX by aligning the two red laser dots on the surface of your material using the standard power focal height adjustment.

Touchscreen Pendant

An optional touchscreen control pendant is available for handheld control of BOQX, including focus control.

MAKTEST INJECTESTER HEUI

Higher Pressure

New Hydraulic System is capable to provide 300 Bar Test Oil Pressure at max 4 L/min flow rate.

Standard Test Oil

Use ISO4113 to test HEUI injectors with precision.

Automatic High Pressure Setting

New Hydraulic System sets pressure automatically, testing continues without interruption.

Hydraulic Electronic Unit Injector Tester

TK1024.03 injectester HEUI is redesigned in accordance to the developments in HEUI technology.

Much Faster Testing

MAKTEST INJECTESTER CRH

Heavy-duty common rail injector test stand

Simple setup with a reinforced clamping mechanism helps reduce overall test time.

TK1029 injectester CRH

TK1029.02 Injectester CRH is designed for testing high pressure and high volume injectors. Its metering capacity is up to 2000 mm3/stroke

An easy solution for a big problem

Independent solution provider for diesel injection problems

4000 kw power are tested precisely on new tk1029.02 new clamping system and spacious injector cabinet allows to mount various geometry injectors.

Maktest injectester CRH

TK1029 injectester CRH is capable to test all injectors for passenger car, light commercial and of course truck engines.

MAKTEST TK1022

Its simple and ergonomic design helps services perform fast and reliable testing on all models of CR injectors.

The TK1022 is a multi-purpose tester for many types of diesel injectors and can test common rail injectors, double stage (double spring) injectors and mechanical injectors.

TK1022 injectester CR Manual is a simple, hand-operated test stand for initial testing of the common rail injectors.

The injector’s pressure holding capability is easily interpreted from the graph of the pressure change.

TK1022 saves precious time and effort for better purposes.

BOSCH EPS 708

Electronic monitoring of service level intervals: Keep the test bench running at its most efficient level.

Intuitive interface: simple for technicians to learn and use with confidence

Integrated database: the most important values for efficient workflows

Rail designed for pressures up to 2,500 bar: Be prepared and extend your current test pressure level (2,200 bar) with the additional kit as diesel technology develops for the future.

Designed for CP1, CP3, CP pumps (Delphi, Denso, Siemens), CRI solenoid valve injectors (Bosch, Delphi, Denso), CRIN solenoid valve injectors (Bosch), CRI Piezo (Bosch, Siemens, Denso): dedicated and versatile test bench

Optional integrated cooling system - an efficient way to use less water

Motor shutdown function: Safety first! Opening the gate immediately shuts off the motor to protect users

Clear and accurate results: Demonstrate your expertise and level of service to customers with a printed test report (optional printer).

MAC-50D

Rated voltage: 220 V, 230 V, 240 V, 460 V

Rated horsepower 50 hp (37 kW)

Current phase 3 Phase

Model 2734

Industrial plants

The model 2734 ultrasonic parts cleaner

is an automated, high efficiency cleaner that utilizes high frequency soundwaves for in-depth pecision cleaning to break down soils in every nook and cranny.

Precision Cleaning

The simple to use

Programmable cleaner takes what once were hours-long, labor intensive, cleaning, efforts and speeds up the process to take as little as 15 minutes.

Maintenance Operations

Model 2734

The ultrasonic parts washer has a 60g tank and 10g auxiliary reservoir made of stainless steeel

TM 514 III

The COMMON RAIL PC FAST

software already comes with the largest database in Brazil and is constantly updated. Friendly operation interface, easy to interpret and use.

Pressure sensor test

Test pressure sensors with ease and precision

Leak test

Performs the pressurization of injector without trigger them to visual check of leaks in nozzles and connections

TM 514 III

TM 514 Common Rail test is used for testing on diesel injection system devices, more specifically common rail systems.

Injector testing

Test one injector at a time, inductive or piezoelectric, checking your electrical and mechanical conditions. For the mechanical conditions, a leakage test and flow test are performed on each injector, measuring the injection and return flow

CORE BALANCER CMT-48 VSR BIG TWIN

CMT-VSR is a long-life balancing machine that is incredibly accurate, efficient and user friendly.

The unit on the right side

Used for balancing of turbocharger core assemblies of vans and heavy duty trucks with a maximum weight of 16 kg.

All-in-one solution

Allows our customers to balance turbocharger core assemblies on passenger cars, commercial vehicles, construction equipment using a single machine.

Cost-saving universal adapter system rotates rotors with a minimum amount of compressed air

Designed for passenger cars and trucks

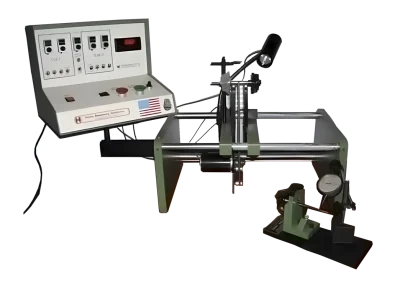

WCB - 30

The WCB-30 is manufactured with reliable solid-state electronics

Lightweight workpiece carriers, permanent magnet DC motor drive system, linear analog meter, and adjustable support bars.

The design of every TURBOCHARGER has a specific ACCURACY of BALANCING in each rotor assembly.

The model WCB-30 allows to determine the quantity and location of the imbalance, as well as to make the proper corrections

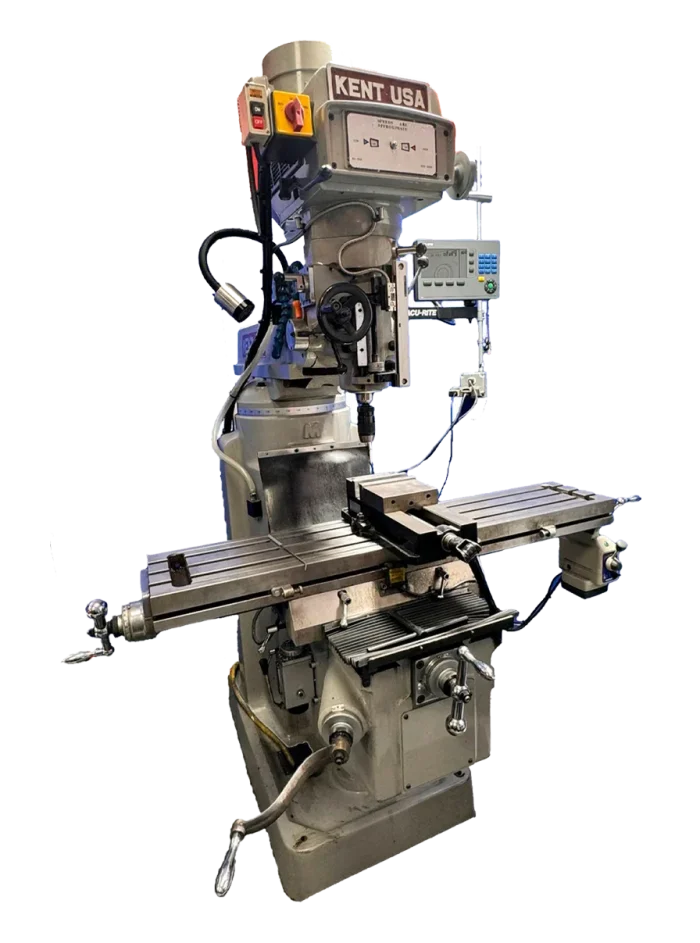

KENT USA KTM-3VK

Milling Machine

The milling machine is a multitasking machine for industrial use, consisting of a horizontal or vertical axis on which rotates a cutting tool called a milling cutter, this machine has a horizontal table on which a workpiece is placed or fixed to give it a specific shape.

Advantage

The main advantage of using the industrial milling machine as a cutting tool lies in the variety of heads we can use for cutting and shaping.

In the body we can find the motor and the computer where we program the cut.

The spindle, which connects the machine to the spindle, also has the work table and even a small lamp to see at all times the cutting of the material to be machined.

The heads perform the cutting or beveling, depending on the depth we give to the cut. There are different types of cutters, depending on the material to be cut and the shape of the cut.

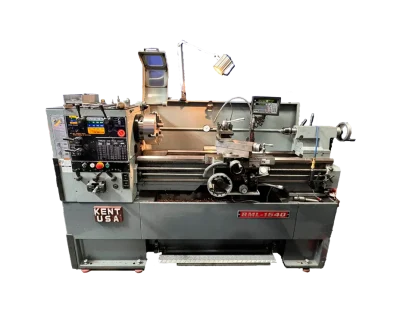

KENT USA RML-1640T

5 HP main spindle motor

ISO 9001 certified manufacturer

36-1800, 12 steps spindle speeds

Foot brake and T-Slot compound Inch/metric reading on dials

Hardened and ground gears and bedways

Inch/metric ruler on tailstock quill

Cast iron machine bedways with full one piece cast base and front loading chip tray for easier cleaning

TURBO TEST EXPERT

The pressure ratio is turbocharger's outlet parameter that defines its performance

It enables the technical condition and its most accurate calibration

Turbo test expert

This model of the machine enables you to restore 100% turbocharger's performance by its calibration according to turbocharger's pressure ratio measured under load at high speeds

MAKTEST INJECTESTER CRB

Maktest inectester CRB

TK1026.03, the new metering system is faster and capable of measuring larger injectors.

Touch to control

Designed for longer and larger injectors to come

The higher and wider working area is designed for the new injectors to come.

Difference from previous versions

Up to 1000mm3 / stroke. Unlike previous versions, TK1026.03 shows instantaneous delivery and return results from the injector.

Fast and accurate measurement system

The CMS metering system shows instantaneous delivery up to 1000 mm3 per injection flow rate.

Automatic testing

The test procedure is performed automatically and a summary of the test report is displayed on the screen when the test is completed.